Ideal Applications

1. High-Speed Conveyor Inspection for Small Parts

In automated conveyor systems, parts often move unpredictably, causing motion blur and inconsistent inspection results. A 5 MP global shutter camera captures the entire image at once, preserving true object shape even at higher speeds. This allows reliable detection of surface defects, missing features, or orientation errors on small mechanical components. The high resolution supports fine detail analysis without requiring multiple cameras. Triggered image capture synchronized with conveyor encoders ensures repeatable timing, while adjustable exposure helps maintain stable image quality under fluctuating factory lighting conditions, reducing false rejects and improving overall inspection confidence.

2. Precision Measurement in Non-Contact Gauging Systems

Non-contact measurement systems require accurate geometry to ensure dimensional consistency. A global shutter sensor prevents image distortion that could compromise measurement accuracy when parts move or vibrate. With 5 MP resolution, the camera provides sufficient detail for precise edge detection and feature localization. Engineers can define regions of interest to focus processing power on critical measurement zones, improving system efficiency. Consistent pixel geometry supports repeatable results over long production runs, making this imaging approach suitable for inline gauging of machined components, molded parts, and precision assemblies.

3. Vision-Guided Robotics for Pick-and-Place Operations

Robotic handling systems depend on accurate visual input to determine object position and orientation. Global shutter imaging ensures that moving targets are captured without skew, allowing reliable coordinate calculation for robotic motion. The sensor’s resolution helps distinguish closely spaced objects and identify subtle orientation cues. Triggered acquisition and digital I/O enable precise synchronization with robot controllers and lighting systems. This combination improves pick accuracy, reduces misgrips, and shortens cycle times in applications such as electronics assembly, packaging automation, and component sorting where repeatability directly affects throughput.

4. Automated Optical Inspection in Electronics Production

Inspecting electronic assemblies demands both detail and geometric stability. A 5 MP global shutter camera delivers distortion-free images of printed circuit boards, ensuring components are evaluated in their true positions. Fine pixel resolution supports detection of solder defects, placement errors, and missing parts. Consistent exposure behavior enables reliable comparison across production batches, even when reflective materials are present. Hardware triggering ensures each inspection image is captured at the correct stage of the process, supporting dependable quality control and reducing costly downstream failures in electronics manufacturing environments.

5. Industrial Tracking and Identification in Logistics Systems

In logistics and material handling environments, objects often move quickly through large fields of view. Global shutter imaging captures sharp frames of moving items, preventing shape distortion that can interfere with identification. High resolution supports accurate reading of labels, markings, or codes on packages and containers. Network-based image transmission allows flexible camera placement across extended conveyor systems. Combined with stable exposure control, this setup enables consistent tracking, sorting, and verification processes, improving operational reliability in warehouses, distribution centers, and industrial transport systems.

Related Products & Accessories

IDS Accessories

-

C-Mount Lenses – Optimized for 1/1.8″ sensors

-

GigE Vision Cables and PoE Injectors – Stable data and power delivery for industrial networks

-

I/O Trigger and Flash Cables – Precise synchronization with external triggers and lighting

-

Industrial LED Machine Vision Lighting – Supports strobe and continuous illumination

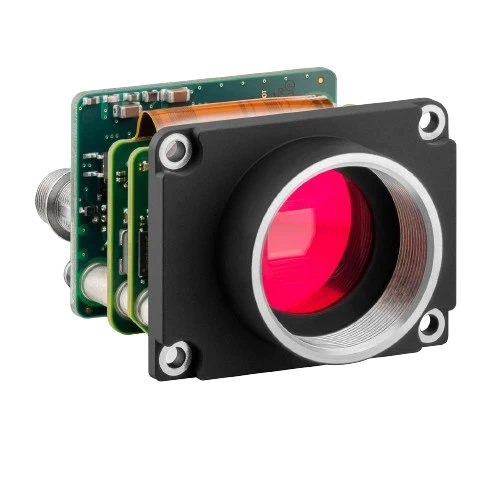

IDS Imaging Cameras

-

GV-51F1SE Series – 5.1 MP Sony IMX547 global shutter GigE cameras for color inspection

-

U3-3271LE Series – Compact USB3 cameras with Sony IMX265 sensors for space-constrained systems